Protecting the world's infrastructure with rope access technology

Protecting the world's infrastructure with rope access technology

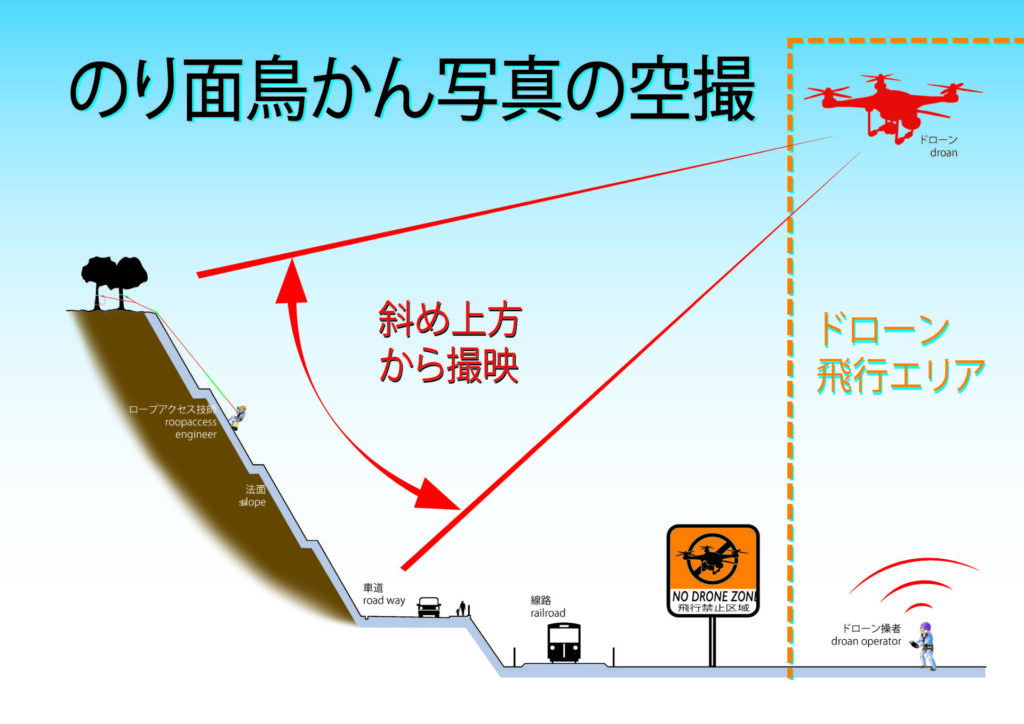

Slope rope access survey is a method where specialized survey technicians themselves use rope access techniques to move safely, quickly, and freely on slopes treated with protective measures such as sprayed mortar, accurately surveying abnormalities and signs of collapse.

Keystone Co., Ltd. conducts high-precision surveys and inspections specializing in slopes, utilizing extensive experience and expertise.

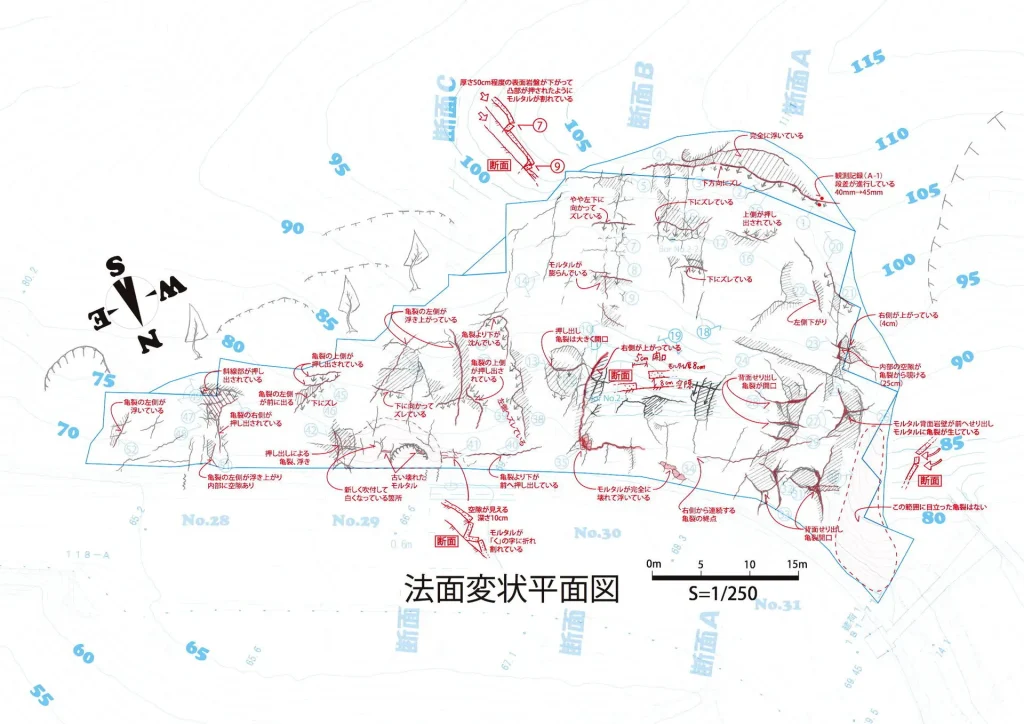

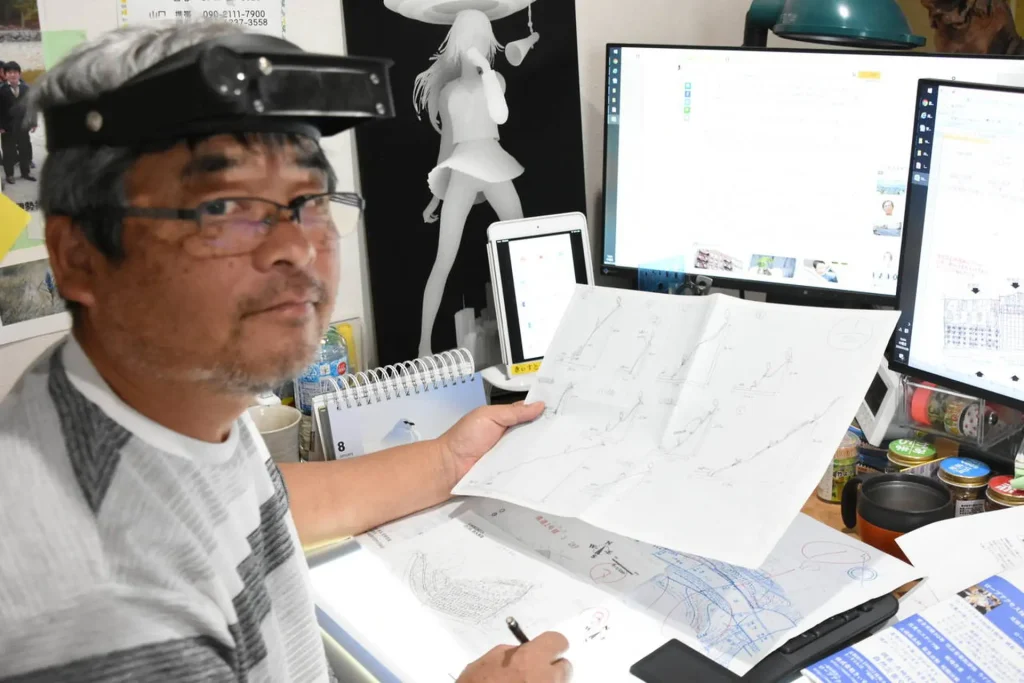

Veteran technicians familiar with geology and bedrock supervise the site, using rope techniques to examine the entire slope in detail. Through full hammer sounding tests, close-up visual and contact observations, even slight deformations and cracks are not missed.

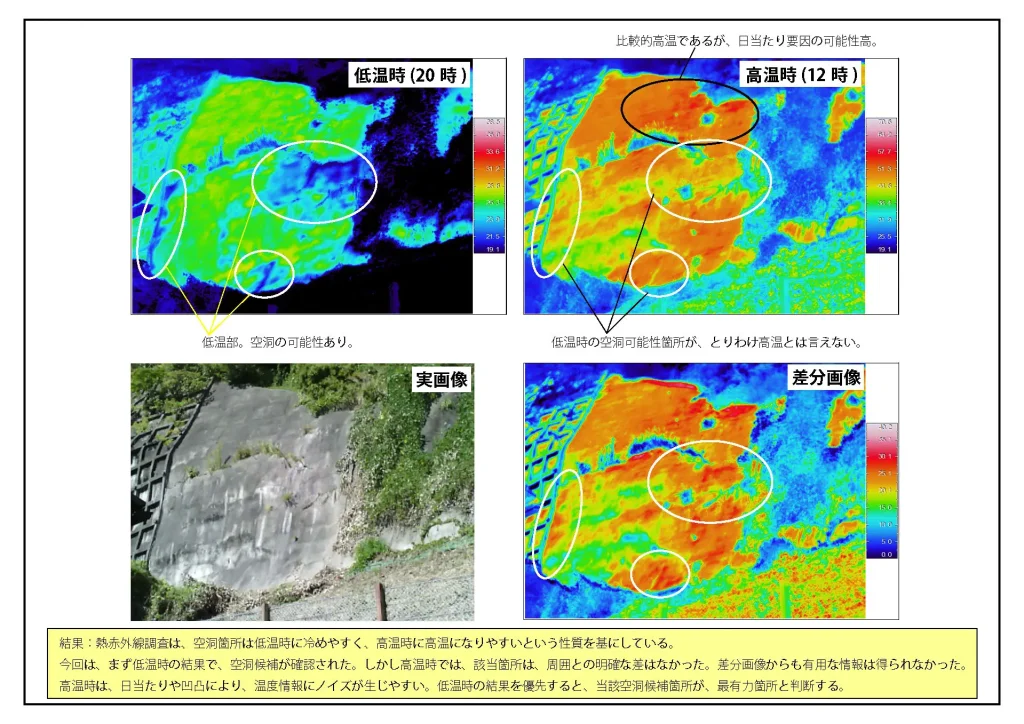

Furthermore, we conduct core drilling surveys and thermal infrared imaging in-house to accurately understand the progression of weathering and loose bedrock. Our deliverables are designed to be easily understood at a glance.

1. When work is required in high or steep locations

2. When scaffolding is inefficient due to cost or time constraints

3. In narrow or restricted-access areas

4. When minimizing impact on the surrounding environment is essential

5. When detailed, close-up visual inspections are necessary

6. When protecting the environment or natural scenery is a priority

Keystone Co., Ltd. is a team of professionals with extensive experience in slope inspections.

Our certified technicians utilize advanced rope access techniques to conduct safe and efficient surveys—even in steep or elevated locations.

Because scaffolding and heavy machinery are not required, traffic control is often unnecessary, which helps reduce costs and shorten project timelines.

We are capable of handling even the most time-sensitive sites and high-traffic areas with flexibility and precision.

Keystone’s engineers possess expert-level understanding of slope topography, rock types, weathering conditions, and geological structures.

• Inferring bedrock characteristics from signs of minor collapses or loosened rock surfaces

• Early detection of collapse precursors such as wedge failures and planar sliding

Based on the results of our inspections, we create damage diagrams and technical reports that are easy to understand at a glance.

Our reports are professionally designed and formatted for immediate use by site supervisors and engineers.

We are also highly flexible when it comes to budget.

We propose optimal solutions based on your financial needs.

• Tight budget? No problem: We deliver maximum value within your constraints.

• Sample Cost Estimate:

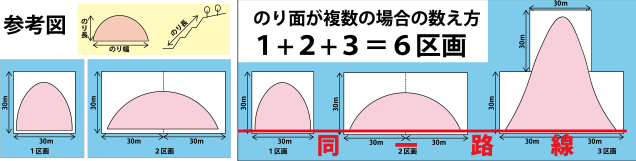

Approximate cost = (Height [m] + Width [m]) × ¥5,000

• For multiple slopes:

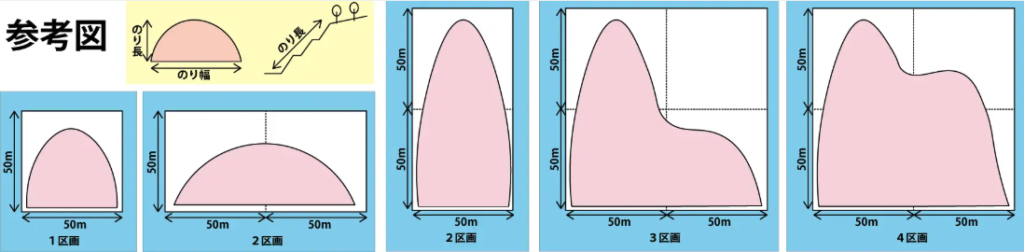

One unit (approx. 30m × 30m area) is estimated from ¥100,000 per section.

We can also accommodate projects with undefined budgets.

Please feel free to contact us for a more detailed quote.

Inspections of designated road earthworks are critical to maintaining road safety and reliability.

Target structures include retaining walls, embankments, cut slopes, and drainage systems.

By utilizing efficient inspection methods and field expertise, we help reduce the risk of accidents while optimizing maintenance costs.

In particular, our use of rope access and drone technology allows for quick, accurate inspections—even under tight schedules and budgets.

• Flexible Response:

We adapt to projects with tight deadlines, multiple inspection sites, or limited budgets.

• Safe and Efficient High-Level Techniques:

Our advanced rope access methods allow us to inspect large areas quickly and safely without the need for scaffolding.

• Use of Cutting-Edge Technology:

By incorporating drones and analyzing aerial data from new perspectives, we improve the overall precision and insight of our investigations.

We prioritize clarity, usability, and completeness in our deliverables.

Our reports are carefully structured to present survey data in a clear and ready-to-use format, utilizing photos and damage diagrams to ensure that site personnel can make immediate use of the findings.

We also offer flexible planning tailored to your budget.

Our team will propose the best solution to meet your financial and project needs.

Example of a Rough Estimate

• Standard unit: 50m x 50m area, starting at ¥100,000

• Total cost is calculated per project, including travel and any additional work as needed

We can also accommodate projects with undefined budgets.

Please feel free to contact us for a detailed estimate or consultation.

[Report Contents]

• Executive summary

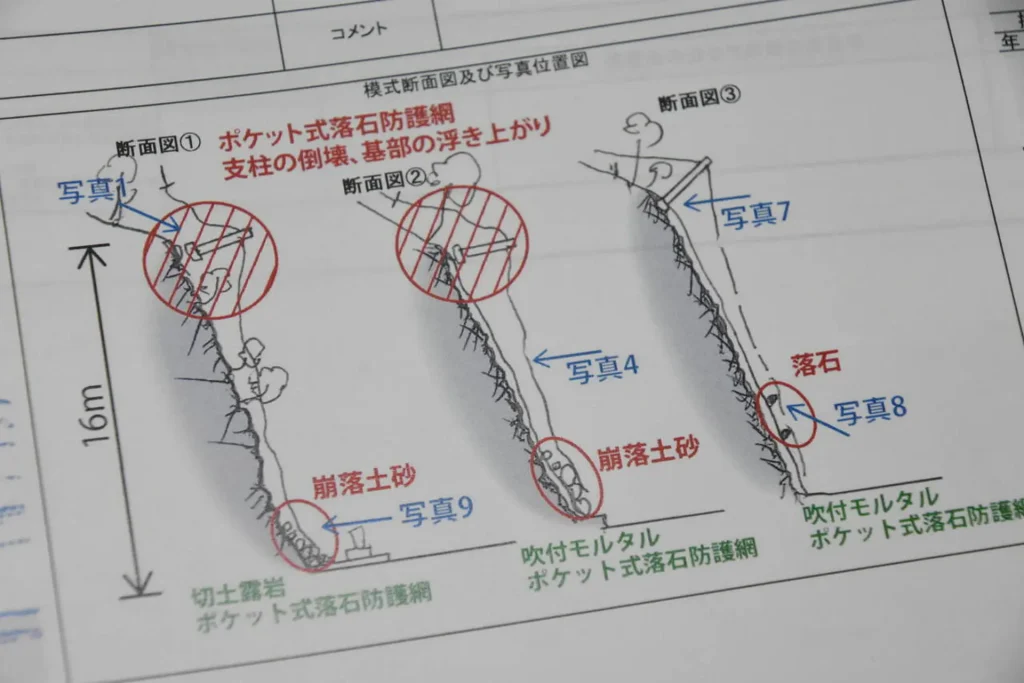

• Survey result development drawings (elevation views, plan views, photographic elevation views, etc.)

• Survey result cross-sectional drawings

• Photographs and photo commentary

* Inspections are conducted in accordance with various inspection guidelines.

* Damage assessment and countermeasure classification determination in accordance with each guideline.

* Inspection result organization is flexibly handled to meet your specific requirements.

These documents provide detailed explanations of our work procedures and technical standards.

Please download and review them as needed.

Q. Is traffic control required?

A. It depends on the site conditions, but generally it is not required.

Q. How do you handle insurance and safety management?

A. We are fully covered by workers’ compensation insurance and have maintained a perfect safety record with zero accidents over the past 33 years since our founding.

Q. Can work be performed in rainy weather?

A. Yes. Our rope access methods ensure safety even in light rain and wind.

Q. How long does it take to complete a project?

A. We are flexible and will adjust the schedule based on your requirements.

Q. How are anchors and rock bolts inspected?

A. Each one is checked individually by tapping and by hand to confirm there are no signs of damage or loosening.

Q. Can rope access be used even when there is a pocket-type rockfall net in place?

A. Yes. While it requires more advanced techniques, our team is fully capable of performing percussion tests and core sampling as needed.

Q. What if vegetation is growing from cracks in the mortar? Can rope access still be used?

A. Yes. This also requires advanced skills, but our experienced staff can handle it without any issues.

At Keystone, we offer highly cost-effective bridge inspection services, driven by skilled and passionate staff.

We always prioritize your budget, applying the best possible solutions within the constraints to ensure your satisfaction.

We never decline a project simply because of a tight budget. On the contrary, we believe that strict conditions bring out the best in our creativity and technical abilities.

For detailed pricing or consultations, please feel free to contact us.

We also offer flexible formatting of inspection results based on your specific needs.